PRODUCTS AND SERVICES FOR THE GLOBAL SOLIDS CONTROL MARKET

STEP Oiltools are a leading global provider of solids control and drilling waste management services to the oil and gas and civil engineering industries. STEP Oiltools have grown significantly since inception in 2011 and are now proud to include some of the biggest names in these industries as our customers.

24 May, 2023

STEP Oiltools will be Exhibiting at this years No Dig Down Under show from the 12-14 September at the Brisbane Convention and Exhibition Centre. We will be showcasing many of our products at the show including separation systems, tooling and screening options. Colin Giles would be delighted to talk through any of our products with you on the day. Please contact colingiles@stepoiltools.com of you would like to arrange a meeting.

23 May, 2023

The horizontal directional drilling (HDD) industry has experienced rapid growth in recent years due to the increasing demand for safe and efficient underground pipeline and utility installations. One of the key components of a successful HDD project is the management of the drilling fluid, which is used to lubricate the drill bit and carry cuttings to the surface. The use of fluid recycling equipment has become increasingly important within this industry, as it provides numerous benefits in terms of efficiency, cost-effectiveness and environmental sustainability. One of the main benefits of fluid recycling equipment is that it significantly reduces the amount of fluid required for each project. The equipment works by cleaning the used fluid, so that it can be reused during the drilling process. This not only reduces the amount of fluid required, but also reduces the amount of waste generated, and the associated costs of disposing of the waste. Another benefit of fluid recycling equipment is that it helps to improve the efficiency of the drilling process. Clean fluid ensures that the drill bit is well lubricated and operates smoothly, reducing the risk of equipment failure and downtime. This, in turn, helps to improve the overall productivity of the drilling process, reducing project times and costs. In addition to reducing costs and improving efficiency, the use of fluid recycling equipment also provides numerous environmental benefits. HDD projects often generate a significant amount of drilling fluid waste, which can be challenging to dispose of. Fluid recycling equipment helps to reduce the amount of waste generated, and ensures that the fluid is cleaned and reused, reducing the environmental impact of the drilling process. There are several types of fluid recycling equipment available from STEP Oiltools, each designed to meet the specific needs of a particular project. For example, centrifuge systems are used to remove fine colloidal solids from the fluid, while shaker based recycler systems are used to remove drilled cuttings, sand and other particles from the fluid. Dewatering systems can be utilised to further clean fluids to recover the water phase for re-use. The choice of equipment will depend on the specific requirements of the project, and the type of fluid being used. The use of fluid recycling equipment within the HDD industry is becoming increasingly important due to the numerous benefits it provides in terms of efficiency, cost-effectiveness and environmental sustainability. By reducing the amount of fluid required and waste generated, improving the efficiency of the drilling process, and reducing the environmental impact of the project, fluid recycling equipment is an essential tool for companies. Whether you are a contractor, utility company or service provider, investing in fluid recycling equipment can help to improve the success and profitability of your HDD projects.

23 May, 2023

Offshore energy operations generate a variety of waste fluids, including slops, which are a mixture of oil, water, and other substances. These fluids are typically stored in tanks on offshore platforms until they can be transported to onshore processing facilities for treatment and disposal. However, this logistics chain can be lengthy and expensive, with associated risks to the environment and health. As such, treating waste fluids, particularly slops, at source using technologies such as the STEP Oiltools ADVANTAGE system can provide numerous benefits to the offshore energy industry. Slops are generated during routine operations such as tank cleaning, bilge water discharge, and deck washdown, and can contain various pollutants such as oil, grease, heavy metals, and other chemicals. If these fluids are not properly treated and disposed of, they can have harmful effects on marine life and the environment. The traditional logistics chain for slops involves transportation of the waste fluids from offshore platforms to onshore processing facilities, which can be located far from the production site. This can be a costly and time-consuming process, as transportation by ship and then road tanker is often required. In addition, transporting slops over long distances can pose risks of spills and accidents during transportation, further increasing the environmental and health risks. This also places a burden on the industry, which must invest in the infrastructure needed to transport these fluids and ensure compliance with regulations regarding the safe handling and disposal of hazardous waste. In contrast, treating waste fluids, particularly slops, at source using the ADVANTAGE system can offer significant benefits to the offshore energy industry. These systems are designed to separate the oil, water, and other substances in the slops, thereby reducing the volume of waste that needs to be transported to onshore facilities. The treated water can then be discharged into the sea or reused for other purposes. This reduces the logistical burden and financial costs associated with transporting slops to onshore facilities. In addition to these economic benefits, treating slops at source also has environmental benefits. By reducing the volume of waste that needs to be transported, the ADVANTAGE system can help to reduce the carbon footprint associated with offshore energy operations. Furthermore, by treating the waste fluids at the source, the risk of spills during transportation is minimised, which can help to protect marine life and the environment. Treating waste fluids, particularly slops, at source using the ADVANTAGE system can provide significant benefits to the offshore energy industry. These benefits include reduced logistical and financial costs and environmental and health benefits through the reduction of carbon footprint, the minimisation of the risk of spills, and the elimination of hazardous waste storage on offshore platforms. With a focus on the environment and lowering the cost of operations, the adoption of reliable and capable slops processing technology helps operators and contractors meet and exceed challenging targets.

10 Jan, 2023

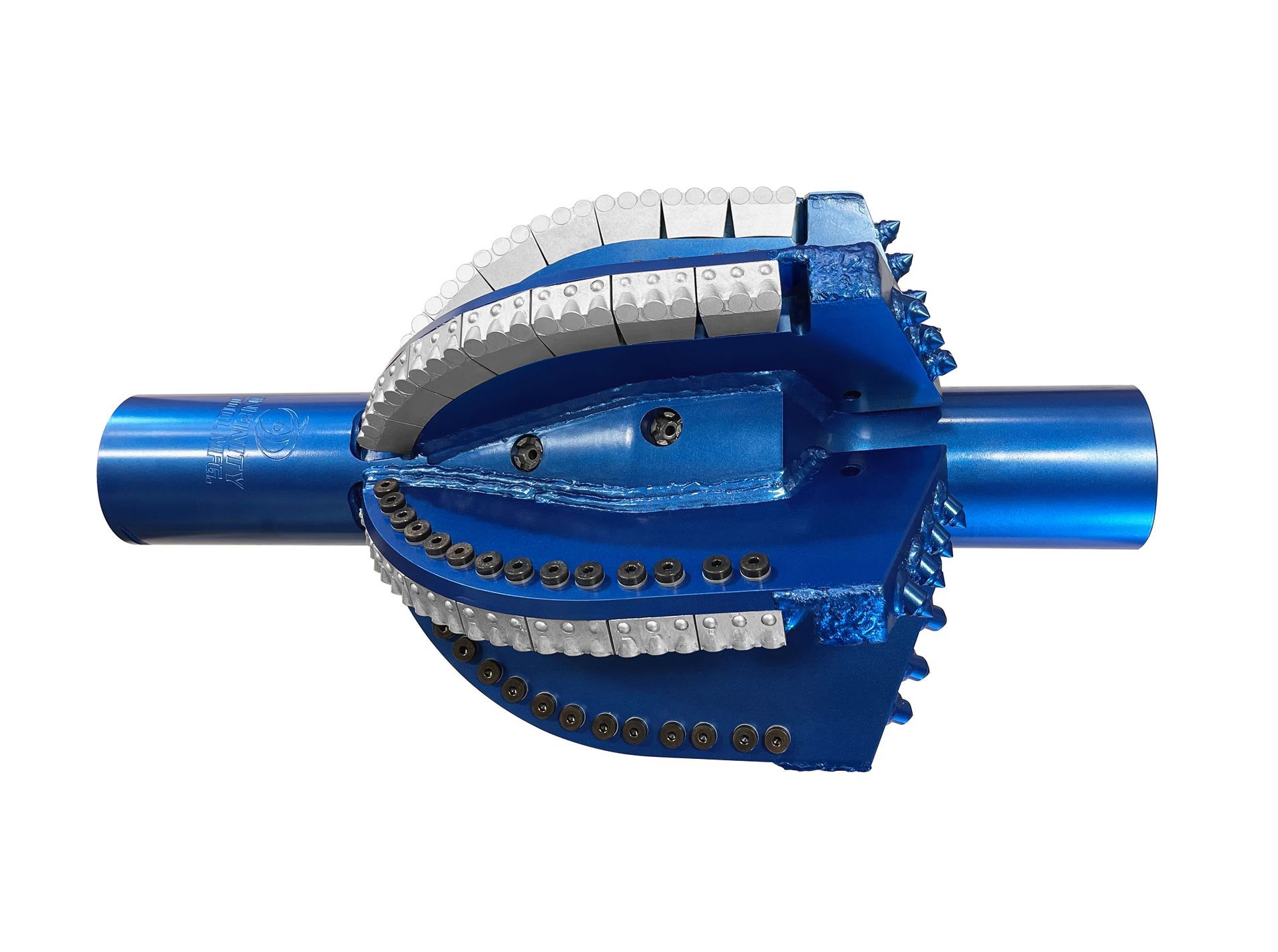

STEP Oiltools (UK) Limited are pleased to announce an exciting new partnership with Infinity Tool MFG, the American rock tool manufacturer. The agreement which commenced in May 2022 includes the distribution of Infinity’s full range of HDD rock tools which provide products for the HDD, Water well Drilling, Geo-Thermal, Construction and Mining sectors. Since 2009, Infinity Tool Manufacturing has been synonymous with manufacturing and supplying market leading rock tools to the drilling industry. Their products are manufactured in a state-of-the-art facility to ISO 9001 international quality management standards. The manufacturing facility is located in Benton, Illinois with distributors and agents located across the globe. STEP Oiltools offers premium slurry separation systems, desanding units, fluid mixing packages and solids control equipment to the Civil Engineering Industry. Operational support bases are located in Germany, the UK, Singapore and Australia. These locations stock equipment, spare parts and consumables, providing a solid distribution network for the industry leading Derrick Equipment™ products. Their experience in this industry spans 30 years and during this time several innovations have been brought to the market that help to increase performance and reduce costs. Rohan Cree, Country Manager for STEP Oiltools UK said: “We are delighted to announce this partnership with Infinity Tool MFG as this will enable us to further support our customers with a complete portfolio of very high-quality drilling tools that can tackle a huge range of ground conditions. Infinity Tool MFG have shown real innovation and understanding of their customers’ needs which can be seen in the design and quality of their tooling. An example is their PDC Shark Reamer which has the ability to be re-dressed with new cutters on location by the customer themselves, reducing the amount of reamers needed for a project and reducing the cost of operations.” STEP Oiltools are keen to offer support for your HDD challenges. To discuss operating procedures when using rock tools or which products are best suited to your ground conditions, please get in touch with STEP Oiltools customer service team - uksales@stepoiltools.com or +44 1224 937188

01 May, 2022

STEP OIltools are celebrating after landing an internationally-recognised award for demonstrating high health and safety standards. STEP Oiltools have received a RoSPA Gold Level Health and Safety Award for working hard to ensure its staff,customers/clients/contractors get home safely to their families at the end of every working day. Organisations receiving a RoSPA Award are recognised as being world-leaders in health and safety practice. Every year, nearly 2,000 entrants vie to achieve the highest possible accolade in what is the UK’s longest-running H&S industry awards. Darren Brown, QHSE Manager for STEP Oiltools said: “We have one again achieved the Gold Award from RoSPA which continues to demonstrate our commitment to health and safety in the workplace. With operational bases across the world, I would like to thank all of the various hard working and committed teams for their dedication to carrying out our work safely.” Julia Small, RoSPA’s Achievements Director, said: “This is a fantastic and well-deserved accomplishment. All our award entrants demonstrate their unwavering commitment and passion for keeping people safe at work. By receiving this recognition STEP Oiltools join like-minded businesses and organisations worldwide, who represent the very best in their approach to Health and Safety. I would like to add my personal thanks for all the work that it has taken to secure this well-deserved award – congratulations to all those involved, who champion and drive up Health and Safety standards every day. You are a fantastic example to others in your sector.” For more information about the RoSPA Awards visit www.rospa.com/awards